we improve the reliability of your asset

“Reliability partner for your critical equipment”

Our Measurement solution

.jpg)

.jpg)

Condition Monitoring Solution for Reciprocating Equipments.

Windrock offers a complete line of portable analyzers and online systems that enable your company to reduce maintenance costs, improve performance, protect critical assets and provide the economic basis for informed decision making.

Not only does Windrock have the analysis equipment to meet your needs, we also have the technical expertise to train and support your staff to maximize the value of the equipment. We offer a graded course of study that allows your analysts to demonstrate the knowledge and skill sets acquired to guarantee the success of your monitoring program.

Windrock is pioneered in condition monitoring of your assets and provide early information on the faults / failures of your compressors / High Speed Engines and rotating Equipment’s:

To increase the life of your asset.

Increase Plant Efficiency & Productivity.

Reduce Maintenance cost.

Reduce Downtime / Man-hours.

Have historical data at your Finger Tips.

Detect early Failures / Problems / Catastrophic Failures / Accidents.

Schedule Planned Maintenance based on the Data collected.

Substantial savings & return on Investment.

“Windrock” Product Range includes:

Continuous On-Line Monitoring Systems.

Windrock Spotlight Monitoring System for Compressors.

Windrock Spotlight for High-Speed Engines.

Portable Analyzers:

Model 6400 PA Performance Analyzer for reciprocating compressors and engines & rotating Machinery

Model 6400 MA Maintenance Analyzer for reciprocating compressors and engines & rotating Machinery

Model 6400 CA Combustion Analyzer for reciprocating compressors and engines & rotating Machinery

Model 6400/DA Dual-Channel Diesel Analyzer – Diesel Engines

Model 6400/DC Combustion Analyzer – Diesel Engines

Model 6400/DV Vibration Analyzer – Diesel Engines

AutoBalance™:

AutoBalance™ provides continuous, peak- pressure balancing for large-bore natural gas-fired engines helping reduce emissions, cut fuel consumption, decrease wear and improve overall machine reliability

SOFTWARES:

Windrock Platinum™ Online Monitoring System.

Windrock Enterprise Asset. Optimization Software.

Windrock MD for in depth Analysis.

“Windrock Digital Services” provide expert solutions for your Assets:

Monitoring your Assets (Compressors / High Speed Engines / Rotating Equipment’s).

Analyze the Data.

Optimize the Data to provide early information on catastrophic Failures.

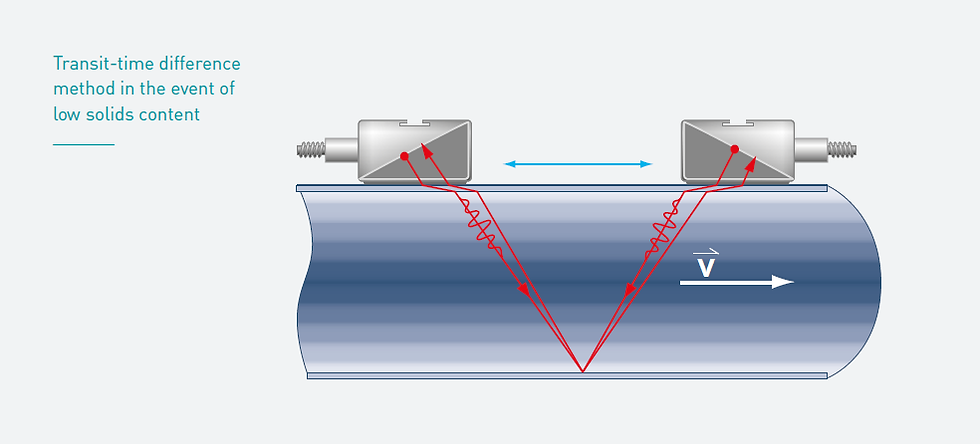

Flow Measurement

Flow Measurement Services is a division of Control Techs Co, a company that specializes in Measurement Solution. The flow experts at Control Techs more than 10+ years of experience in your hands. FMS is an organization dedicated to measuring Flow and BTU usage in various types of Oil & Gas, Petrochemical , Utility, commercial, and industrial applications. FMS will meet all your metering and sub-metering tasks in new or existing systems, whether it is a domestic water meter for your tenant or a fuel-oil pipeline meter from your supplier.

What we offer:

➔ Confirm & certify flow rates of new and existing systems:

– Volume flow meters.

– BTU meters & HVAC applications.

– Our calibration meters are NIST.

➔ Provide formal reports & data analysis based on NIST-traceable portable reference meter.

How we can help

➔ Provide traceable third party metering.

➔ Existing meter calibration.

➔ Reveal inefficient operation.

➔ Resolve billing issues.

What makes FMS different:

➔ The use of non-invasive ultra-sonic flow meters so you don’t have to shut down any process or systems.

➔ The ability to measure and capture low velocity flow rates that no other metering technology can measure.

➔ Over 10+ years industry experience.

Why flow measurements and verification:

➔ Optimizing process efficiency and control.

➔ Increasing product through-put and yield.

➔ Decreasing the use of consumables

➔ Reducing energy costs.

➔ Reassuring employee and community safety.

➔ Complying with environmental regulations.

➔ Simplifying maintenance and avoiding unplanned maintenance.

Contact Me

Building No. 7051, Prince Sultan Road, As Salamah، As Salamah, Jeddah 23525, Saudi Arabia

+966503350236